| Quick Details | ||

| Gearing Arrangement: Helical | Output Torque: 4144-239765 (N.m) | Rated Power: 23-1850(kw) |

| Input Speed: ≤1500 (rpm) | Output Speed: 15-188 (RPM) | Place of Origin: Zhejiang, China (Mainland) |

| Model Number: DBY series | Brand Name: XINGHAIWANG | certification: ISO9001:2008 |

| material: cast iron housing or other . | material: aluminlum alloy or cast iron housing . |

| Packaging & Delivery | |

| Packaging Details: |

standard export packing ,inner packing is opp bag, outside packing is wooden case, or According to the customer's requirements packaging. |

| Delivery Detail: | 20 days after confirmation |

Specifications

1:small size,compact,lightweight,saves space for mounting,various installt

2:min:1 set

Technical data:

1,output torque:4144-239765(N.m)

2,rated power:23-1850(kw)

3,input speed:≤1500 (rpm)

4,output speed:15-188(rpm)

5,transmission ratio:≥8-50

6,series:2-3

7,Model no. :DBY160,DBY180,DBY200,DBY224,DBY250,DBY280,DBY315,DBY355,DBY400, DBY450,DBY500,DBY560;

DBY160-56 type cone of cylindrical gears reduction gear, carrying capacity is strong, small volume, low noise, applicable to the axis, the shaft at right angles, decorate the mechanical transmission.

if you have any other needs ,pls donot feel trouble to contact me .

1. Summary

Cone cylindrical gear reducer is the outer meshing gears transmission structure of input and output axis in vertical state, the main transmission parts adopt high quality alloy steel to manufacture.

Gears by carburization, quenching, and grinding process manufacturing,6 degree precision.

The product has the advantages of high loading capacity, long life, small volume, high efficiency, and light weight, etc.

The standard number of this series speed reducer is JB/T9002-1999, which is our country's generation-substituting product. It can replace SS type vertical shaft speed reducer and ZQ, ZL old type speed reducer, and so on. Also it can replace the same type speed reducer imported from foreign countries.

2. Usage and scope of application

2.1 Usage

Cone cylindrical gear reducer (Hereinafter referred to as speed reducer), which use in the rotating equipment for input and output shaft in vertical direction layout. It mainly used in belt conveyor and other conveying equipment, it also can be used in metallurgy, mine, chemical engineering, coal, building materials, light industry, petroleum, and other general machinery.

2.2 Scope of application

2.2.1 The maximum input speed of speed reducer should be no larger than 1500r/min;

2.2.2The peripheral speed of gear should be no larger than 20m/s;

2.2.3 The ambient temperature is -40~+45℃. When ambient temperature is lower than 0℃, we should heat the oil lubrication before starting. (Heat pipe is needed)

3. Speed reducer type and mark

3.1 Type

3.1.1 DBY type is the secondary rotating hard surface gear reducer, DCY type is third rotating hard surface gear reducer, and the secondary and third rotating is involutes cylinder helical gear.

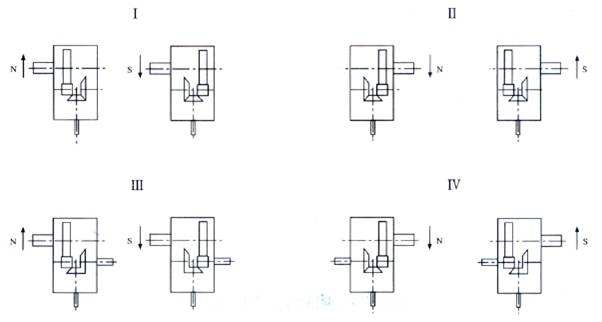

3.1.2 Speed reducer can be divided into ⅠⅡ、Ⅲ、Ⅳ four assembly types according to output shaft type, and also can be divided into clockwise and anticlockwise two types according to output shaft rotating directions. (Face output shaft)

3.2 Mark

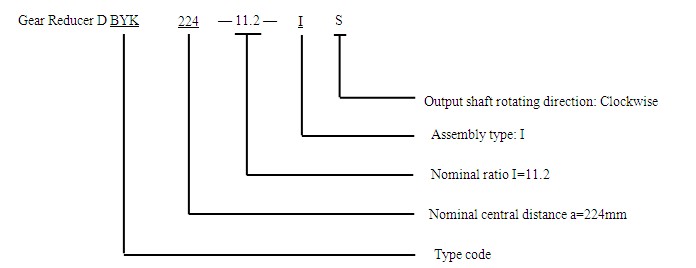

3.2.1 The mark code of speed reducer include speed reducer type, nominal central distance, nominal ratio, assembly type and output shaft rotating direction.

3.2.2 Mark example

Speed reducer

3.2.3 Need to configure the backstop should be another statement

(D ribbon conveyer code ,B(C)-double stage(third stage)transmission ,Y-hard gear surface gear, K-hollow shaft)

4.Outline size、assembly size、loading capacity and thermal power.

4.1 Assembly type

Picture1 DBY assembly type

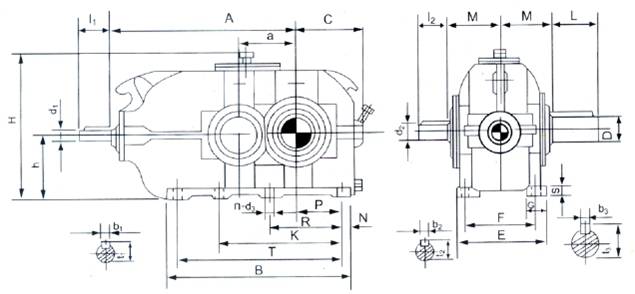

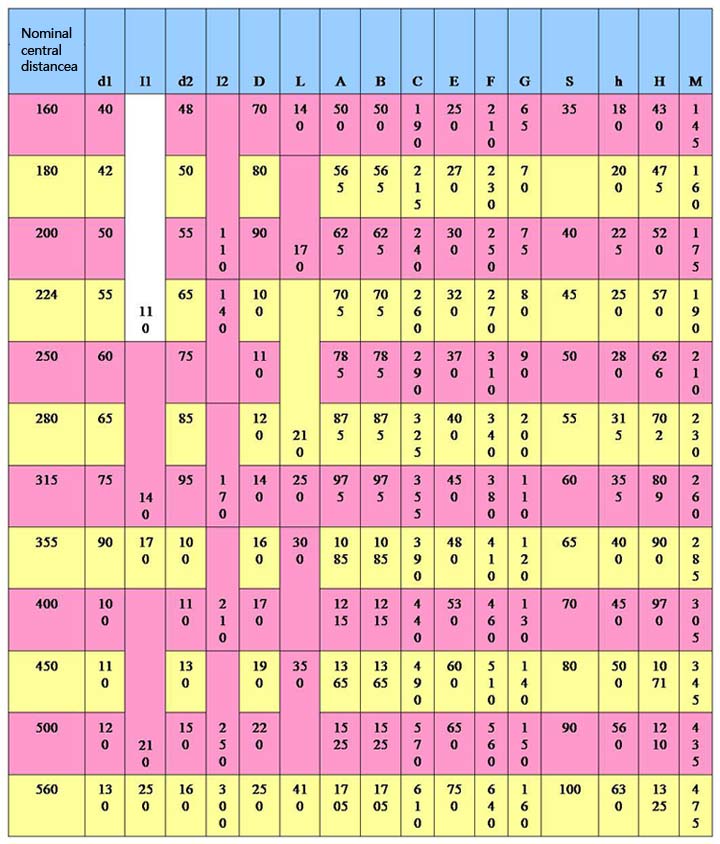

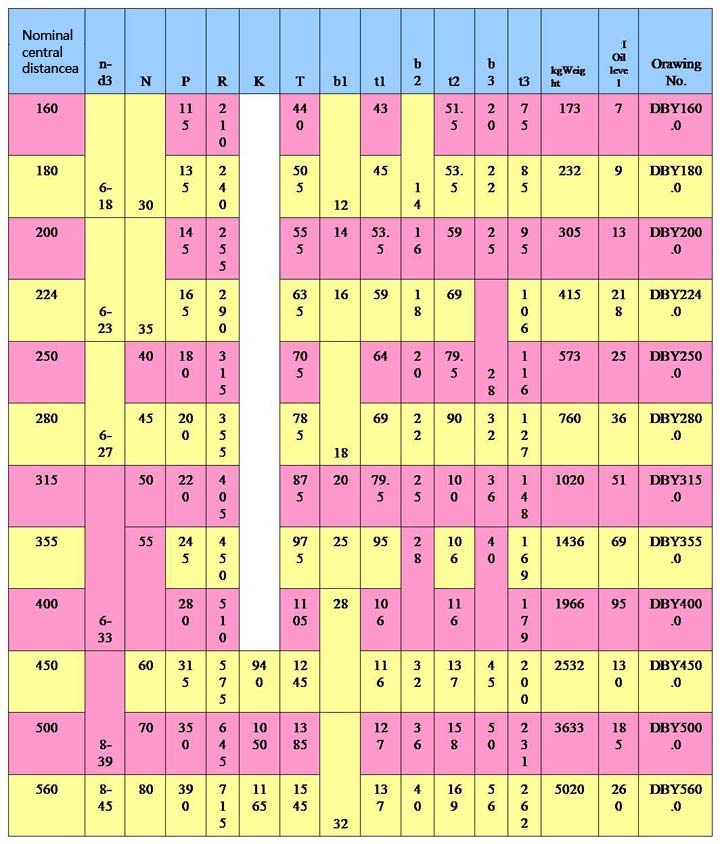

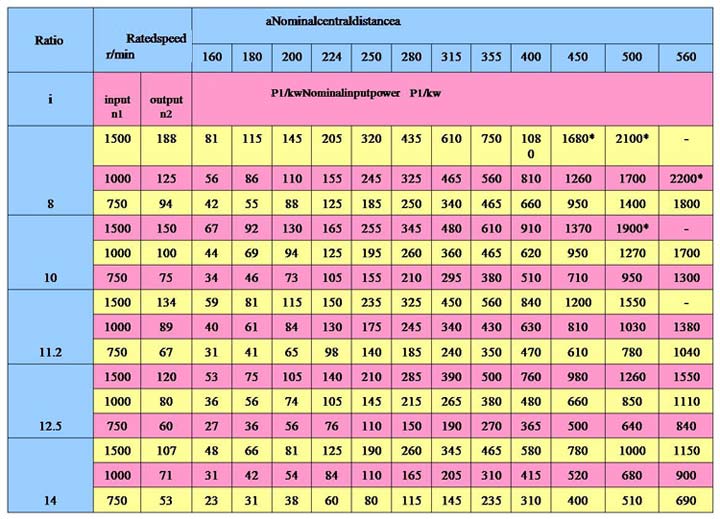

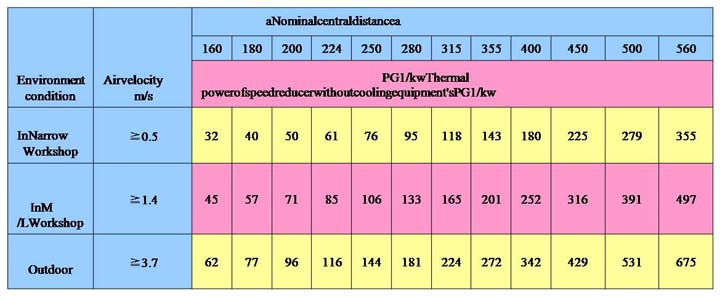

4.2 DBY speed reducer outline dimension and loading capacity and thermal power.

Outline dimension see picture3、form 1;loading capacity see form2;thermal power see form 3.

Picture3 DBY speed reducer

Form 1 DBY type speed reducer outline dimension mm

Form 2 DBY,DBYK Type speed reducer loading capacity

Note: * It needs to adopt recycling oil lubrication.

Form 3 DBY,DBYK type speed reducer thermal power

Note: The thermal power PG2 of speed reducer attached with cooling pipe can be designed as request.